Blog

A Beginner’s Guide to IoT PCB Assembly

The Internet of Things (IoT) has revolutionized how we interact with the world around us, offering unparalleled connectivity and intelligence to everyday objects. At the heart of this technological marvel lies the Printed Circuit Board (PCB), a crucial component that [...]

Exploring Long PCB Boards: A Beginner’s Guide

Have you ever wondered what makes the gadgets around us work so seamlessly? From your smartphone to the microwave in your kitchen, there's a hidden hero inside many of these devices: the Printed Circuit Board (PCB). Today, let's dive into [...]

The Comprehensive Guide to Big PCB Boards

Have you ever opened up an electronic device and wondered what the green board inside was? That, my friend, is called a PCB or Printed Circuit Board. It's the backbone of nearly all electronic devices today. But, not all PCBs [...]

Exploring Thin PCB Boards: A Simple Guide

Have you ever wondered what powers the heart of your smartphone or what's behind the scenes of your sleek laptop? The answer lies in a technology so vital yet so overlooked: the Thin PCB (Printed Circuit Board). In this article, [...]

Understanding Thick PCB Boards: A Simple Guide

Have you ever wondered about the brains behind your electronic devices? What makes them tick, buzz, and light up? The answer often lies in a hidden hero: the Printed Circuit Board (PCB). Specifically, we're diving into the world of thick [...]

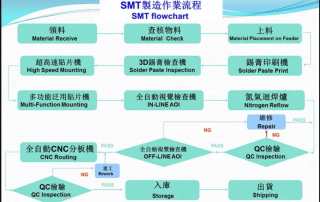

SMT production process

Program the SMT placement machine According to the BOM position map provided by the customer, program the coordinates of the location of the components. Then carry out the first piece with the SMT chip processing data provided by the customer. [...]

IC Package Substrate

IC Package Substrate, also known as IC Package Substrate, is the key carrier of integrated circuit industrial chain packaging and testing links. At present, IC Package Substrate is usually made of traditional multilayer or HDI board as the basis. Play in [...]

high-frequency PCB and high-speed materials for 5G printed circuit board

Introduction of high-frequency PCB and high-speed materials for 5G printed circuit board In 2019, 5G will be commercialized preliminarily, the upstream raw materials of core materials such as high-frequency copper cladding are basically similar to those of traditional CCL. After [...]

What’s HDI PCB board?

The HDI PCB board is thin and small, and can realize high-density interconnection PCB board. HDI PCB stands for High Density Interconnect PCB. HDI board is the Japanese enterprise to the high density interconnection printed circuit board has always been [...]

Electronic Parts supplier in China

Hitech Group has more 10 yeas experience on Electronic Parts sourcing area in China. We can provide convenient quick turn parts sourcing for more than 1,000 of our customers globally. To maintain all our customers, we have plenty of global [...]

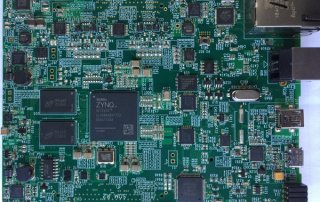

Printed Circuit Board Assembly Service

Printed Circuit Board Assembly Service Printed Circuit Board Assembly is one of our major services, Also, HITECHPCB build from rigid pcb, flexible printed circuit boards manufacturing, components sourcing to PCB assembly. Check out this list of some of the high-quality PCB [...]

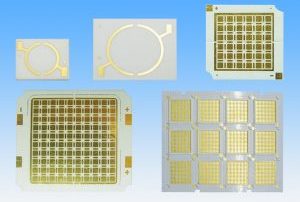

FR4PCB vs. Aluminum PCB vs. Copper base PCB vs. Ceramic PCB for led headlight

For the PCB boards now in application to LED headlight, there are mainly four kind of materials, FR4 PCB, Aluminum PCB, Copper PCB and Ceramic PCB. It is a good deal to understand the distinctions for these four types PCB. [...]

How to select the surface treatment process of HASL, ENIG and OSP for printed circuit boards?

How to select the surface treatment process of HASL, ENIG and OSP for printed circuit boards? After finish the PCB design, we need to choose the surface treatment process of the printed circuit board. At present, the commonly used surface [...]

PCB assembly SMT Processing Technology

Control of PCB assembly SMT Processing Technology During PCB assembly patch processing, quote management should be implemented for solder paste, SMT adhesive, and component loss, as one of the control contents of key processes. PCB assembly processing and production directly [...]

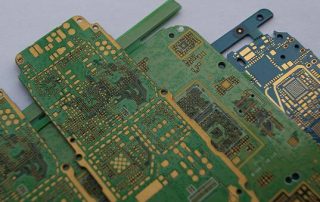

PCBA assembly Appearance Inspection Instructions

Printed circuit board assembly (PCB assembly, PCBA), often use abbreviations—— PCBA, is an important electronic parts, is the support of electronic components,the provider of the electronic circuit connection.Because it is produced by using electronic printing technology, it is called "printed" [...]

Tips of high frequency PCB (RF PCB) design

In order to achieve more reasonable design and better anti-interference ability for high frequency PCB(Microwave RF PCB), design engineer should consider the tips as following: Use inner layer as power ground layer, which will have the effect of shielding and [...]

Anti-static requirements for PCB assembly processing

Since PCBA assembly processing often involves a variety of static-sensitive electronic components and some processing technologies that have certain requirements for electrostatic protection, certain anti-static requirements must be followed in PCBA processing. Electrostatic warning signs are mainly used for posting, [...]

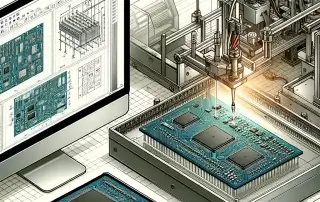

A Look Inside The PCB Design Process

A Look Inside The PCB Design Process Printed Circuit Board (PCB) design is a critical aspect of electronics manufacturing. It involves designing the layout, placement of components, and interconnection of a PCB before it is manufactured. The PCB design [...]

Successful Flex Circuit Design Guidelines

Successful Flex Circuit Design Guidelines With the use of sensors and technology in everything from mobile phones to refrigerators to automobiles to wearable medical devices, circuit boards are a component in many different types of products. In today’s world of [...]

High Speed PCB Design

Hitechcircuits’ experts work closely with customers to provide consulting and guidance for EMC and SI design throughout the PCB design process in the following areas: System-Level Architecture and floor-planning, main boards, daughterboards, backplanes, connectors, cables, grounding. Enclosure design and [...]