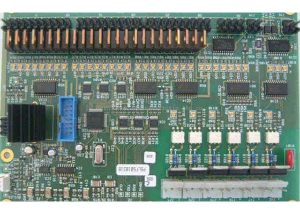

Printed Circuit Board Assembly Services

Printed Circuit Board Assembly Services

Printed Circuit Board Assembly Service ( PCB Files & BOM List, please send to [email protected] ( Fast Quote )

Printed Circuit Board Assembly is a process that requires knowledge not just of Printed Circuit Board components and assembly but also of printed circuit board design, Printed Circuit Board fabrication and a strong understanding of the final product. Circuit board assembly is just one piece of the puzzle to delivering the perfect product the first time.

Printed Circuit Boards (PCBs) are across many industrial and consumer electronics, used in products ranging from remote controls to military weaponry. The versatility of PCBs comes from their lightweight, compact, and flexible construction, which can be adapted to suit circuits of any complexity. Though PCBs are relatively commonplace, their complexity makes it critical to source new circuit boards from reliable suppliers. Printed Circuit Board Assembly services harness these complexities.

Hitech Group offers comprehensive Printed Circuit Board Assembly services that help our customers fully realize their designs. We have extensive experience working with customers in a broad range of highly innovative industries, including Communication, Aerospace & Defence, Automotive, Industrial control, Medical equipments, Oil & Gas, Security, and so on.

Printed Circuit Board Assembly Process

The PCB assembly process can look very different depending on the type of PCB and the order volume. Our PCB assembly process include any of the following steps, depending on the client’s needs:

Automated Assembly

Automated PCB assembly is ideal for components that are difficult to solder by hand and high-volume production runs. It is the fastest and most efficient means of producing consistent circuit boards.

Reflow

Reflow soldering is the most common method used for efficiently soldering SMT-mounted components. The process uses a reflow oven to melt solder onto a pre-heated and pre-soaked PCB.

Wave Solder

Wave soldering is another efficient method that involves applying flux to an entire PCB surface, heating the board, and then applying molten solder to the whole heated board.

Selective Solder

Selective solder is a more precise variation of wave soldering used to apply flux locally rather than the entire PCB. Instead of using a “wave” of molten solder, it uses nozzles to apply solder exactly where needed.

Hand Insertion and Soldering

Hand insertion and soldering may be used when project constraints require manual through-mounting.

Point-to-Point Wiring

Point-to-point wiring is a labor-intensive manual assembly method that involves hand-mounting and soldering all components on a circuit board. This process is used as an alternative to PCBs in specific applications, including repairs to vintage electronics.

Automated Optical Inspection (AOI)

This automated inspection process uses cameras to scan the PCB for defects and quality issues.

Solder Paste Inspection (SPI)

The SPI process closely inspects solder paste deposition before part placement.

These additional services represent one of our most significant advantages over our competitors. Many companies cannot provide the X-Ray capabilities or ionograph testing necessary for industries requiring immaculate boards. For example, our medical clients leverage our ability to measure contamination down to ppm on a single square centimeter.

Ball Grid Arrays (BGA)

Ball Grid Arrays are used on highly complex PCBs to mount microprocessors and other integrated circuit components. BGAs provide more interconnection pins to facilitate faster and more reliable component connections. While BGAs and micro-BGAs provide superior performance, they are also exceedingly difficult to solder. Incorporating BGAs and micro-BGAs into your PCB assembly requires partnering with an expert Electronics Manufacturing Services provider like Hitech Group.

Hitech is an expert PCB manufacturing & assembly company that proudly supplies PCB assembly solutions to businesses of all sizes in China.

Our industry-leading PCB assembly processes create PCBs of the highest quality. Our expert team is made up of in-house trained professionals who have the experience and expertise to create dependable PCBs and utilise our PCB assembly technology. Through our strong network of well-proven PCB assembly and manufacturing partners, we can provide the most advanced and nearly limitless capabilities for your prototype or production PCB application. Save yourself the trouble that comes with the procurement process and dealing with multiple components vendors. Our experts will find you the best parts for your final product.

We offer the following PCB assembly services:

Quick-turn prototype printed circuit boardassembly

Turn-key printed wiring board assembly

Partial turn-key PCB assembly

Consignment assembly

RoHS compliant lead-free PCB assembly

Non-RoHS assembly

Conformal coating

Final box-build and packaging

Prototype PCB Assembly

PCB prototyping has always been one of our most requested services, whether it’s PCB prototype fabrication or assembly. Our expert engineers will check and test your layout to ensure the correct prototype is fabricated and assembled on the first assembly run. Through our network of PCB component suppliers and SMT assembly engineers, we can ensure you a quick turn around and top quality circuit board. We offer low volume circuit assembly for prototyping with DFM and DFT to eliminate possible issues in your product.

The process of PCBA manufacturing

Electronic Components sourcing – PCB fabrication- SMT Patch – DIP plug-in – board Assembly testing – Finished product assembly

PCB Assembly requires electronic components and consumables

Printed Circuit Board, Electronic Components, Solder Wire, Solder Paste, Welding Rod, Solder Preform (depending on welding type), Scaling Powder, Welding Platform, Wave Soldering Machine, SMT Equipment, Testing Equipment

PCB manufacturing

Hitech Group provides a full set of PCBA manufacturing and part of PCB assembly manufacturing. In the full range of PCB assembly manufacturing, we handle PCB production, material procurement, online order tracking, incoming material certification/quality inspection, and final assembly. In some PCB manufacturing, you can order PCB and some materials by yourself, and we complete other parts.

How to get a one-stop inquiry of PCBA manufacturing?

BOM quotation, please send your BOM to Hitech Group, tell the number of PCB to be made, we will give you a PCBA quote within 24 hours. BOM must include quantity, tag number, manufacturer name, and manufacturer model.

Before the PCB assembly is delivered, we will carry out various tests on it.

– Visual inspection: general quality inspection

– X-ray test: check whether there is short-circuit cold welding or bubble problem in BGA, QFN, and another welding.

– Automatic optical detection: check whether there are false welding, short circuit, few parts, polarity reversal, etc.

– Online testing

– Function test (according to the test steps you provided)