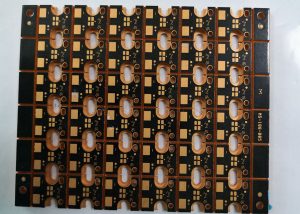

Aluminum PCB

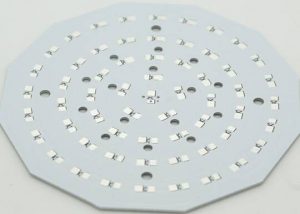

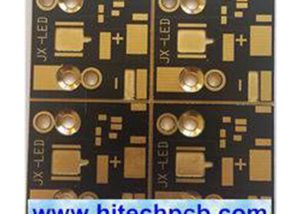

Aluminum PCB & Metal Core PCB & LED PCB Circuit board

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected] .

What is aluminium PCB board ?

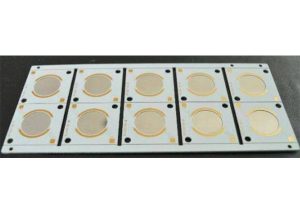

Aluminium PCB board, also named Aluminium based PCB, metal clad (MCPCB) PCB, insulated metal substrate(IMS or IMPCB) PCB, thermally conductive PCBs, etc. Aluminum printed circuit board ( PCB ) is a unique metal-based copper clad laminate with good thermal conductivity, electrical insulation performance and mechanical processing performance. It is composed of copper foil, thermally conductive insulating layer and metal substrate. It is generally including single layer, double layer and multi layer aluminum pcb board.

The structure of aluminum printed circuit boards

Generally speaking, the PCB aluminum substrate is composed of a circuit layer, a thermally conductive insulating layer and a metal base layer; it can be divided into three layers:

Circuit layer: equivalent to the copper clad laminate of an ordinary PCB, the thickness of the circuit copper foil is 1 to 10 oz. The circuit layer (that is, copper foil) is usually etched to form a printed circuit to connect the various components of the assembly. Generally, the circuit layer requires a large current-carrying capacity, so thicker copper foil should be used, with a thickness of 35μm~ 280μm;

Insulation layer: The insulation layer is a layer of low thermal resistance thermally conductive insulating material. The thickness is 0.003 to 0.006 inches. It is generally composed of a special polymer filled with special ceramics. It has low thermal resistance, excellent viscoelasticity, thermal aging resistance, and can withstand mechanical and thermal stress. It is the core technology of aluminum-based copper clad laminates. Our aluminum printed circuit boards have obtained UL certification.

Metal base layer: The metal base layer is the support member of the aluminium pcb, which requires high thermal conductivity, generally aluminum plate will be used, copper plate can also be used (copper plate can provide better thermal conductivity), suitable for conventional machinery such as drilling, punching and cutting processing.

Main usages and applications of aluminium PCB board:

- Audio devices: input, output amplifiers, balanced amplifiers, audio amplifier, preamplifier, power amplifier etc.

- Power Supply: switching regulator, DC / AC converter, SW regulator .

- Telecommunications electronic equipment: high-frequency electric amplifiers, filtering appliance, transmitter circuit etc .

- Office automation equipment: electric motor, drivers etc .

- Automotive: electronic regulator, ignition, power controllers etc .

- Computer: CPU board, floppy drive, power device etc .

- Power Modules: converter, solid-state relay, power rectifier bridges etc .

- Lamps Lighting: with the promotion of energy-saving lamps, Aluminum base PCB , are widely used on LED lights.

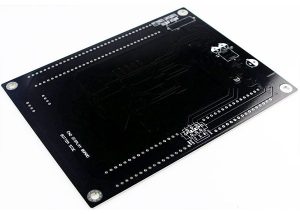

Aluminum pcb vs fr4 pcb board

FR4 board is a code name for the grade of flame-retardant material. It represents a material specification that the resin material must be able to extinguish by itself after burning. It is not a material name, but a material grade. Therefore, there are many types of FR-4 grade materials used for pcb, but most of them are composite materials made of so-called Tera-Function epoxy resin, Filler and glass fiber.

FR-4 PCB board, according to different uses, industry insider generally call them: FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4 , Fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board , FR-4 light board, FR-4 fiberglass board, epoxy glass cloth board, epoxy glass cloth laminate, circuit board drilling pad etc.

Main technical features and applications of FR-4 board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for high-performance electronic insulation requirements products, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber board, precision star gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation support spacer, insulation backing plate, transformer insulation plate, motor insulation, grinding gear, electronic switch insulation board, etc.

The aluminum pcb board is a metal-based copper-clad laminate with good heat dissipation function. Generally, a single-sided aluminum PCB is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, it is also designed as a double-sided board, and the structure is circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are multi-layer boards, which can be formed by bonding ordinary multi-layer boards with insulating layers and aluminum bases.

Compared with traditional FR-4 PCB, aluminum pcb circuit boards have the following advantages:

- Good thermal conductivity. The metal layer of the aluminum pcb board can quickly dissipate heat, transfer the heat of the device, minimize the thermal resistance, and have good thermal conductivity.

- More environmentally friendly. Aluminum-based pcb boards do not contain substances harmful to human health and the environment, and are more environmentally friendly than FR-4 circuit boards.

- High durability. FR-4 pcb may be warped, bent, cracked etc during production and transportation; ceramic substrates are also more fragile. Aluminum pcb circuit boards make up for the shortcomings of FR-4 boards and ceramic substrates, have longer durability, and avoid board cracks caused by production and transportation.

- Higher performance. The circuit layer of the aluminum-based PCB board is etched to form the circuit. Compared with the traditional FR-4 pcb board, under the same line width, thickness, etc., the current carried by the aluminum pcb is higher than that of the FR-4 pcb board.

Features of aluminum material that used to manufacturing Aluminium PCB Board

Regarding Aluminum PCB or wrote as Aluminium PCB, there are different types of Aluminum which used for the laminate of Aluminium base pcb, the brief introduction as below.

There are mainly three different types of metal aluminum base that commonly used, including 1000 series, 5000 series and 6000 series, the basic features of these three series aluminum base are as follows:

(1) 1050, 1060, 1070 are the typical types of 1000 series, 1000 series is also known as pure aluminum base, which is the purest of all the series, the purity can reach more than 99.00%. Because this series do not contain other technical elements, so the production process is single and simple, the price is relatively cheap as well, It is currently the most commonly used series in conventional industry. nowadays, 1050 and 1060 are most widely used in the market. 1000 series aluminium base determine the range of the minimum aluminium content according to the last two digits, such as series 1050 , the last two digits are 50, according to the international brand naming principles, its aluminum content must be more than 99.5%, it is unqualified if less than 99.5%. Our country standard (GB/T3880-2006) is clearly stipulated in 1050 must reached 99.5% aluminum content. Same as 1060 series that aluminum content must be above 99.6%.

(2) 5000 series include 5052, 5005, 5083, 5A05 series. 5000 series belongs to alloy aluminum base series which is commonly used, the main elements is magnesium, about 3-5% magnesium element, so it is also known as aluminum and magnesium alloys. The main features are low density, high tensile strength and high elongation rate. Under the same area, the weight of the aluminum magnesium alloy is lower than other series, so is the reason why often used in aviation, such as aircraft fuel tank. In other conventional industries are widely used as well. The processing technology belongs to the series of hot rolled aluminum base, therefore can do oxidation processing. At present, 5052 is the most widely used in 5000 series.

(3) 6061 belongs to 6000 series, which mainly contains magnesium and silicon two kinds of elements. 6061 is a kind of cold treatment of aluminium products, applicable to against corrosion, oxidation demanding. The general characteristics of 6061: excellent interface characteristics, easy to coating, high strength, good workability, strong corrosion resistance. 6061 aluminum base typical applications: aircraft parts, camera parts, coupler, ship accessories and metal, electronic components and connectors, etc.

Advantages of aluminum PCB printed circuit boards

- It is more suitable for SMT process;

- Meet the requirements of RoHs;

- The heat dissipation has been effectively treated, thereby reducing the operating temperature of the module, prolonging the service life and improving the reliability;

- The volume is decreasing, reducing the assembly area of radiators and other hardware, reducing product volume, and reducing hardware and assembly costs;

- Good mechanical durability, better than ceramic circuit boards made by some simple processes.

Disadvantages of aluminum pcb printed circuit boards

- Higher cost: Compared with other cheap PCB products, the price of aluminum-based PCB boards accounts for 30% of the total product price.

- At present, the mainstream manufacturer can only make single-sided PCB boards, and it is difficult to make double-sided aluminum PCB boards. At present, single-sided aluminum PCB boards are relatively skilled in China, and the process and technology of multi-layer aluminum PCB boards are relatively mature in foreign countries. Good news is, through years of aluminum pcb board designing and manufacturing, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards.

- The thermal conductivity test method and the test result do not match, the thermal conductivity of the dielectric layer and the thermal conductivity of the aluminum-based PCB board are different to a certain extent.

- The material standards for aluminum-based copper-clad PCB boards are not unified. There are CPCA industry standards, national standards, international standards, etc.

- If the thickness of the copper foil does not meet the standard, it will cause some phenomena such as burning the circuit and exploding the power supply. However, we never occur such problems.

Does HiTech Circuits offer technical support for designing Aluminum PCBs?

Yes, HiTech Circuits provides comprehensive technical support, including design assistance and recommendations to optimize your PCB for manufacturing efficiency and performance.