Project Description

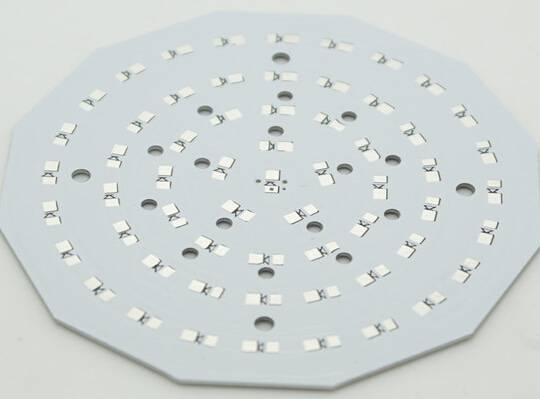

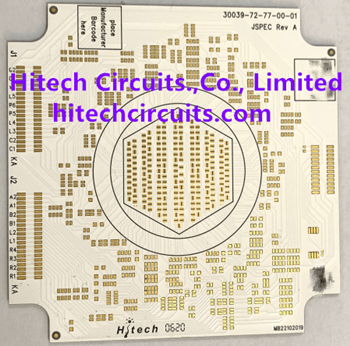

Bergquist Aluminum pcb

Bergquist Aluminum pcb board manufactured by Hitech, the Thermal Clad circuit board materials are available from The Bergquist Company in four different thermal conductivities, High Power Lighting (HPL), High Temperature (HT), Low Modulus (LM) and Multi-Purpose (MP). If you are looking are Bergquist Aluminum based pcb manufacturer in China, please contact [email protected] .

Technical Parameters

- Bergquist aluminum pcb

- Base Material: Bergquist material Aluminum pcb

- Layers: 1

- Thickness: 1.5mm

- Copper thickness: 1Oz

- plating process: Immersion gold

- Description: LED MPCB

What’s Bergquist Aluminium PCB?

Bergquist is one of USA company, which produce Aluminium base material sheet, the performance is perfect, Aluminium base material sheet is widely used for led PCB power industry.

Now that Power LEDs are capable of unprecedented levels of white LED brightness and luminous efficacy, they are being used in many products that are part of our daily lives. Although today the initial cost of Power LEDs is higher, many applications have demonstrated LED PCB lighting as the most cost or energy efficient solution for future installations. Bergquist provides critical thermal management support for a myriad of Power LED applications that include: medical, signage, signal, transportation, aircraft, automotive, security, portable, theatrical, commercial, residential and street lighting Power LED packaging has evolved to adapt to higher power dissipation demands. For these Power LED packages, the lowest possible thermal resistance packaging is paramount to a long and reliable service life. By combining Bergquist thermal management materials with this new and innovative packaging, progress in both light output and light quality can be achieved.

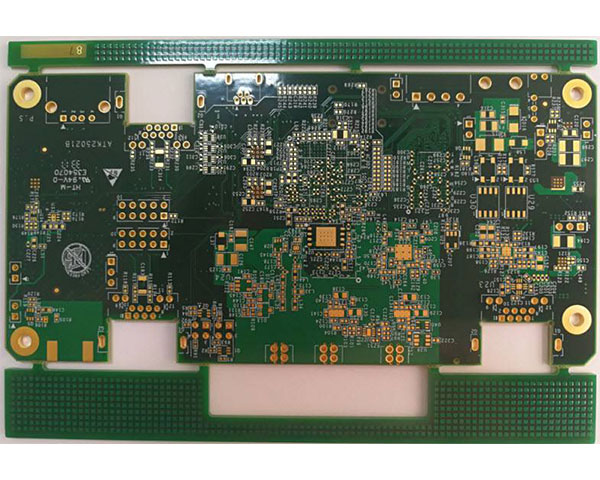

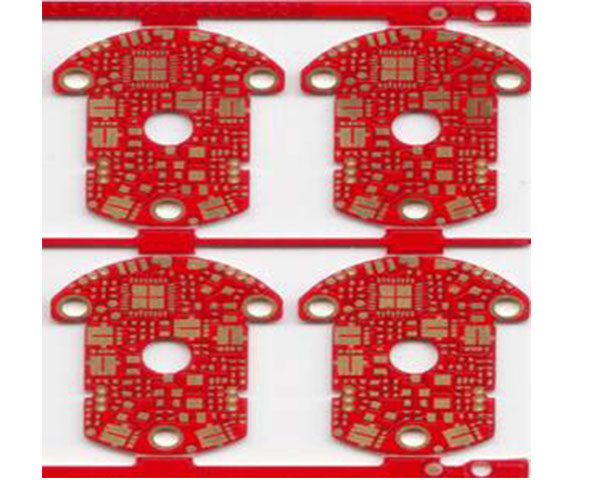

Printed Circuit Board Comparison

Metal core PCB and standard FR-4 are commonly used circuit board materials in conjunction with Power LEDs. Bergquist’s Thermal Clad dielectric is a thin, thermally conductive layer bonded to an aluminum or copper substrate for heat dissipation (see illustration below). The key to Thermal Clad’s superior performance lies in its dielectric layer. This layer offers electrical isolation with high thermal conductivity and bonds the base metal and circuit foil together. Other manufacturers use standard prepreg as the dielectric layer, but prepreg doesn’t provide the high thermal conductivity and resulting thermal performance required to help assure the lowest possible operating temperatures and brightest light output for high-intensity LEDs PCB. Thermal Clad circuit board materials are available from The Bergquist Company in four different thermal conductivities, High Power Lighting (HPL), High Temperature (HT), Low Modulus (LM) and Multi-Purpose (MP).

Packaging Conclusion

Good practice suggests that you reduce the thermal resistance of that layer with Thermal Clad dielectric instead of FR-4

Bergquist Aluminium PCB materials types:

Bergquist MP-06503

Bergquist HT04503

Bergquist HT07006

Bergquist HPL-03015

Bergquist HR T30.20

If you want to get Bergquist materials date sheet, please email to us, [email protected]

Or you can review Bergquist website: www.bergquistcompany.com