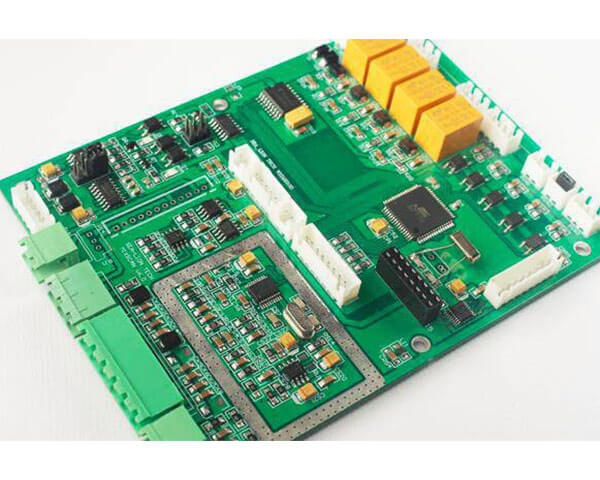

Control of PCB assembly SMT Processing Technology

During PCB assembly patch processing, quote management should be implemented for solder paste, SMT adhesive, and component loss, as one of the control contents of key processes. PCB assembly processing and production directly affect product quality, so it is necessary to control the processing parameters, process, personnel, equipment, materials, processing inspection, workshop environment and other factors.

Key positions must have a clear post responsibility system. All operators must be strictly trained and assessed, and they must be certified to work. PCB manufacturers should formulate a set of standardized production management methods, such as the implementation of the first piece inspection, self-inspection, mutual inspection and inspector inspection system.

1. Mass Production Management. The non-conforming product control procedures should clearly stipulate the separation, marking, recording, review and processing of non-conforming products. Generally, SMA revisions shall not exceed three times, and component revisions shall not exceed two times.

2. Repair and Maintenance of PCB factory Production Equipment. Important equipment is regularly inspected by full-time maintenance personnel to ensure that the equipment is always in good condition, track and monitor the status of the equipment, find problems in time, take corrective and preventive measures, and repair in time.

3. Production Environment.

Water and electricity supply system.

Environmental requirements of PCB assembly production line—temperature, humidity, noise, cleaning.

PCBA site (including component library) anti-static system.

The entry and exit system of the PCBA patch processing line.

4. The production site should be reasonably set and marked correctly; the materials in warehouse should be classified and stored in the products, neatly stacked, and the records are consistent.

5. Civilized Production. Including: clean and free of debris; civilized work, no brutal and disorderly work behavior. On-site management should be systematic, inspections, assessments, and records, also Hitech do arranging, rectifying, cleaning, literacy, and service every day.

If you’re interested in our products, please kindly email to Cynthia: [email protected]