The Advantages of Surface Mount Technology (SMT) in PCB Designing Services

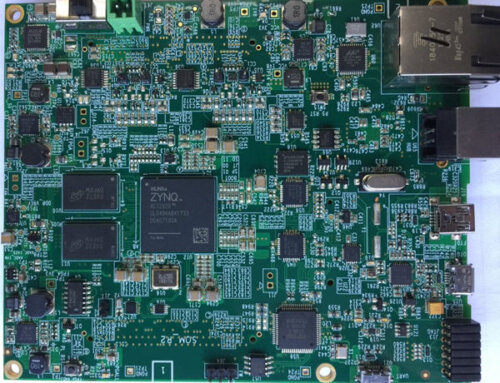

PCB designing has become a critical component in the manufacture of electronic gadgets. Printed Circuit Boards (PCBs) are used to support and connect electronic components. Several manufacturing techniques exist in the market, but this blog discusses Surface Mount Technology (SMT). With SMT, the electronic components are attached to the board by being soldered to the surface. But why should you leverage SMT in your PCB designing services? This blog will detail some key factors that make SMT beneficial in the context of PCB designing services.

1. Space Saving

In comparison to traditional through-hole technology (THT), SMT is an advantageous technology that saves space. SMT follows the surface of the PCB, which allows for smaller and more compact boards. This reduced size is valuable as it makes PCBs a viable component for devices with smaller dimensions. As the size of electronic gadgets reduces, the demand for smaller PCBs increases. Thus, to maximize space and save on cost, it is recommended to leverage SMT in PCB design services.

2. Enhanced Signal Performance

The electronic components used in SMT are smaller than their THT counterparts. The smaller sizes enhance the performance, particularly for high-frequency applications. The reduced length of signal paths minimizes noise interference and enhances signal speed. Also, SMT’s design approach increases the density of components on the board. This, in turn, increases the number of electronic components which can be put on a board, leading to improved functionality and greater performance.

3. Faster Manufacturing

Speed of production is a vital aspect of manufacturing. Finding ways to optimize manufacturing processes can lower costs, reduce labor requirements, and, ultimately, reduce the cost of your products. SMT has shorter assembly times since the components are placed on the board with a pick-and-place machine. SMT can handle several components at once, while THT is a labor-intensive process. In this regard, leveraging SMT in PCB designing services will offer increased efficiency, lowered costs, and shorter delivery times.

4. Greater Design Flexibility

SMT technology provides greater design flexibility for manufacturers. The small nature of SMT components allows them to be closely grouped together on the board. This, in turn, offers PCB designers more space to lay out the board as they see fit. The enhanced flexibility available in SMT allows PCB designers to create more custom, tailored solutions for their clients. This flexible design approach is particularly important for applications where the environment is challenging. Whether it is a space-restricted situation or high-temperature environment, SMT allows you to tailor your design needs to suit any environment.

5. Reduced Costs

The cost considerations of electronic manufacturing are important to consider for manufacturers. SMT offers lower costs than THT. SMT technology uses less material since it’s smaller and has automated assembly and placement. The automated approach also minimizes the cost of labor and flux, thereby reducing overall manufacturing costs. In this way, SMT is not only efficient but cost-effective, which can help businesses save money and reduce the price of their products.

Conclusion:

In conclusion, Surface Mount Technology is an efficient and effective technology for PCB design services. When compared to traditional through-hole technology, SMT offers better signal performance, design flexibility, cost efficiency, faster manufacturing, and space-saving designs. With these advantages, the usage of SMT for PCB designing services is made even more valuable, which could help you to improve your overall manufacturing processes, satisfy your client’s needs, and give your business a competitive edge.