Why Printed Circuit Boards Remain in High Demand?

Printed Circuit Boards (PCBs) have been a staple component of electronic devices for decades. Their reliability, durability, and flexibility have made them indispensable in many industries, including automotive, medical, aerospace, and telecommunications. Despite the arrival of new technologies such as 3D printing and nanotechnology, PCBs continue to dominate the market. In this blog, we will explore the reasons why printed circuit boards remain in high demand.

1. PCBs Offer High Performance

PCBs are designed to connect different electronic components and enable them to perform various functions. They can accommodate complex circuits and offer high speed, accuracy, and consistency. PCBs can handle high frequencies and power, which is crucial in applications such as communication systems, mobile devices, satellite equipment, and medical equipment. PCBs also offer low signal noise, electromagnetic interference, and crosstalk, which enhances their performance.

2. PCBs Are Flexible and Customizable

One of the biggest advantages of PCBs is their flexibility in configuration and customization. They can be designed and fabricated to match the specific requirements of a particular device or application, such as size, shape, thickness, and number of layers. They can also accommodate various electronic components, such as resistors, capacitors, diodes, and transistors, which make them versatile and adaptable. PCBs can be designed for mass production, prototyping, or low-volume requirements, which makes them suitable for many different industries.

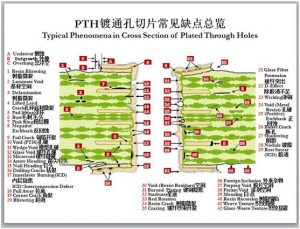

3. PCBs Are Cost-Effective and Reliable

PCBs offer a high level of reliability and durability, which translates into reduced maintenance, repair, and replacement costs over time. They are made of high-quality materials such as fiberglass, copper, and solder mask, which offer excellent thermal and mechanical properties and resistance to corrosion, moisture, and temperature changes. PCBs can also withstand harsh mechanical and environmental conditions, which is important in industries such as automotive, aerospace, and marine. PCBs are cheaper than alternative technologies such as wire-wrapping or point-to-point wiring, which makes them cost-effective for many companies.

4. PCBs Are Environmentally Friendly

PCBs are environmentally friendly because they are made of materials that are easy to recycle or dispose of. The majority of PCBs are made of fiberglass and copper, which are highly recyclable materials. PCBs can also be designed to minimize waste and reduce the use of toxic materials such as lead and mercury. PCBs conform to industry standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment), which regulate the use and disposal of electronic devices.

5. PCBs Allow for Innovation and Advancements

PCBs have remained in high demand because they facilitate innovation and advancements. Advancements such as flex PCBs, rigid-flex PCBs, and high-density interconnect (HDI) PCBs have emerged, which have allowed for even greater levels of flexibility, customization, and performance. PCBs are also essential to the development of new technologies such as the Internet of Things (IoT) and autonomous vehicles. PCBs allow for the miniaturization of electronic devices, which has revolutionized industries such as wearables, medical devices, and consumer electronics.

Conclusion:

PCBs remain in high demand because they offer high performance, flexibility, cost-effectiveness, reliability, and environmental friendliness. They allow for innovation and advancements in various industries and are compatible with new technologies such as the IoT and autonomous vehicles. PCBs are an essential component of the electronic devices that we use every day, and they will continue to play a critical role in the evolution of technology and industry in the future.