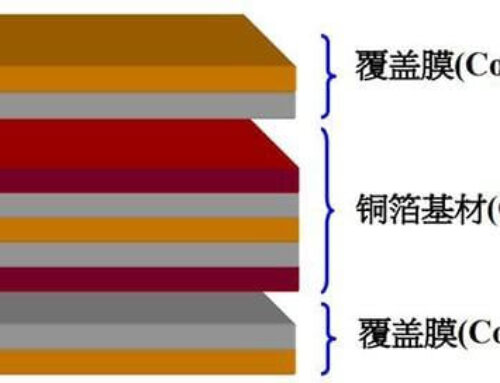

Flexible circuit boards are necessary in numerous applications where a design requires the circuit to be bent within the electrical equipment or electronic device. However, it is not desired to have the flexible circuit board bend adjacent to connectors, mounted components, solder joints, and hole patterns. In these instances, a stiffener needs to be designed in to add rigidity and stability so that the flex circuit performs reliably.

Main Stiffener Types

FR4

FR4 can be bonded using a flex adhesive, that is thermally set, or a with a pressure sensitive adhesive (PSA). Standard thicknesses for FR4 range from 0.008″ up to 0.059″. When utilizing an FR4 stiffener on a circuit board with a plated-through holes, the stiffener needs to be placed on the same side of the flex as the connector or component to allow for access to the solder pads on the opposing side. On surface-mount technology (SMT) flex circuit boards, the FR4 stiffener needs be placed on the opposite side of the components.

Polyimide

Polyimide film stiffeners are attached using a thermal set adhesive. They can be utilized with many types of components and or connectors but are specifically required for zero insertion force (ZIF) connectors. The polyimide stiffener allows the design to meet the necessary thickness level specifications of ZIF connectors.

Stainless Steel

Stainless steel can provide the thinness that is required in these areas while providing added stiffness necessary. However, one thing to keep in mind is that stainless steel much more costly than other types of materials.

Aluminum

Aluminum is another alternative to the polymer or glass/epoxy stiffeners commonly used for flexible circuit boards. The main reason that aluminum is used involves applications where a lot of heat may be generated.

To move and dissipate that heat from components, aluminum is added as a stiffener as the metal acts as a heat sink. So, components and connectors can remain cool as the aluminum will draw away the heat. Just like with stainless steel, aluminum will cost more than when using either polyimide or FR4 materials.