Project Description

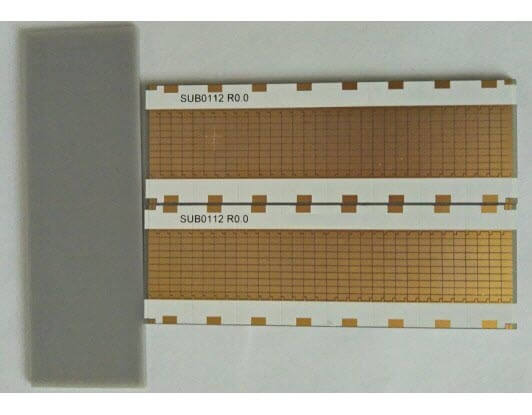

Ceramic PCB manufacturing

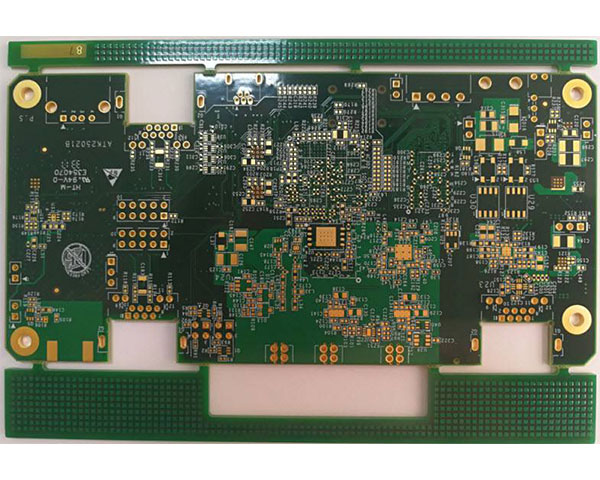

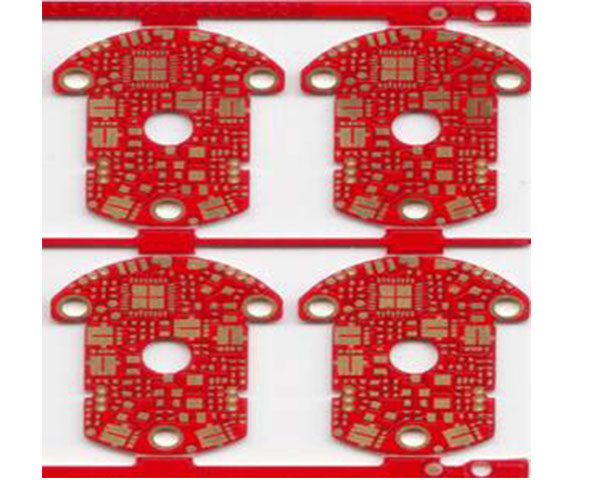

Ceramic PCB have good high-frequency and electrical performance, and have high thermal conductivity, excellent chemical and thermal stability. Excellent corrosion resistance, it widely used in semiconductor and microelectronic circuit packaging pcb, High-brightness Led chip carrier board, automotive electronics and lighting components, high-power electronic component heat dissipation materials, etc.

What is Ceramic PCB?

Ceramic PCBs provide best source of reacting point for printed circuits due to two reasons, high thermal conductivity and low coefficient of thermal expansion (CTE). The ceramic PCB is highly unique and useful because it is a complete replacement of traditional printed circuit boards having simple structure and increased performance.

Ceramic PCB Board Categories

There are three categories of ceramic PCB boards.

- Thick Film Ceramic PCB

It is thicker than expulsion and spurting technology. Gold or silver is used as a conductor and is printed on the ceramic boards.

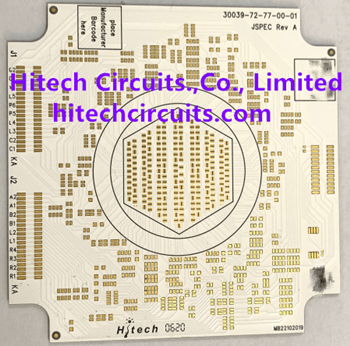

- Thin Film Ceramic PCB

This film fit on the ceramic substrate.

- Direct Copper Bonded (DCB) Ceramic PCB

In this technology, the special procedure bonds the copper foil and the core on one or both sides using appropriate temperature and pressure.