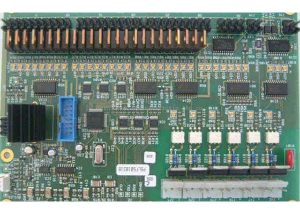

PCB Assembly

Circuit Board Manufacturing & PCB Assembly & Electronic Assembly service & electronics manufacturing company – Hitech Circuits Co., Limited

As leading one-stop PCB Assembly services provider in China, Hitech Group offers high quality, cost effective and express PCB board products and provides PCB manufacturing, electronics assembly manufacturing, components sourcing, Box build assembly and PCBA testing services for our customers.

For full turn-key circuit board assembly, we take care of the entire process, including Printed Circuit Boards fabrication, components sourcing, order tracking, continuous monitoring of quality and final PCB board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

What is PCB assembly

The circuit board before the assembly of electric components is called Printed Circuit Board. After the soldering of all the elements on the board, it is known as Printed circuit Board Assembled, we called PCB assembly. The complete process of component’s assembly is called Printed Circuit Assembly or Printed Circuit Board assembly or PCB board assembly. In this process, different automatic and manual assembly tools are used. We are assembler that offer PCB assembly.

What’s the difference between Printed circuit board vs PCB Assembly?

PCB is a printed circuit board because it is made by electronic printing, so it is called a “printed” circuit board. PCB is an important electronic component in the electronic industry, it is electronic base. It is the support of electronic components and the carrier of electrical connection of electronic components. PCB has been widely used in the production of electronic products.

PCB Assembly generally refers to a processing flow, which can also be understood as the finished circuit board, that is, PCBA can only be counted after the processes on the PCB are completed. PCB refers to an empty printed circuit board with no parts on it. The above is the difference between PCB and PCBA.

SMT (surface mounted technology) and DIP (Dual In-line Package) are both ways to integrate parts on the circuit board. The main difference is that SMT does not need to drill holes on PCB, but in dip, it needs to insert the pin into the drilled hole.

SMT mainly uses the mounting machine to mount some micro and small parts on the circuit board. Its production process is PCB positioning, solder paste printing, mounting by the mounting machine, reflow oven, and inspection.

The dip is a “plug-in”, that is to insert parts on the PCB board. It is a kind of plug-in integrated part when some parts are large in size and not suitable for mounting technology. Its main production processes are back glue, plug-in, inspection, wave soldering, plate brushing, and finished inspection.

Flexible Volume PCB Assembly Service

Our PCB assembly services go above and beyond what the average PCB assembly company will do. We offer a variety of flexible circuit board assembly services for the different stages of your product development, including:

• Prototype PCB Assembly: See how well your PCB design works before generating a large order. Our quality prototype PCB assembly allows us to deliver a quick prototype, so you can identify any potential challenges in your design fast and optimize the quality of your final boards.

• Low-Volume, High Mix PCB Assembly: If you require a number of different boards for specialized applications, HitechPCB is your company.

• High-Volume PCB Assembly: We are equally as skilled at cranking out large PCB assembly orders as we are at delivering small ones.

• Consigned & Partial PCB Assembly: Our consigned PCB assembly services meet IPC Class 2 or IPC class 3 standards, are ISO 9001:2015-certified and are RoHS-compliant.

• Full Turnkey PCB Assembly: Also ISO 9001:2015-certified and RoHS-compliant, our turnkey PCB assembly allows us to take care of your entire project from start to finish, so you can step in and start taking advantage of the finished product right away.

From SMD to through-hole and mixed PCB assembly projects, we do it all, including free Valor DFM/DFA checks and function testing to verify the quality of your boards, with no minimum cost requirements or added tooling charges when you reorder.

Hitech Circuits integrates quality ISO certified systems and innovative assembly and packaging technologies to deliver market-leading consumer electronic products. From product assembly through enclosures to testing and packaging, Hitech’s SMT lines utilize the most advanced technologies in the industry including:

Quick turn pcb assembly Flip Chip Technologies

0201 Technology

Lead-Free Solder Technology

Alternative PCB Finishes

Early supplier involvement

Design and engineering support

PCB manufacturing and PCB assembly

Backplane assembly

Memory and optical modules

Cable and harness assembly

Plastic injection molding

Precision machining

Enclosures

Integration of hardware and software

BTO and CTO services according to your needs

Reliability testing

Lean and Six Sigma quality processes

We offer both human and automated PCB assembly services for PCBA Prototype

Our PCB assembly processes use both human and automated services. Larger PCB assembly projects can benefit from the speed and accuracy of our automated service, while PCBA prototypes more detailed work can be checked in-house by one of our expert team members.

Surface Mount Technology assembly (SMT Assembly)

At Hitech, we have capabilities to utilize surface mount technology to assemble your PCBs, using our pick and place machine. We use surface mount assembly technology as it is more cost-efficient and reliable than other, more traditional PCB assembly methods. For example, with SMT assembly more electronics can be included in a smaller space on a PCB. This means PCBs can be customised much more easily and efficiently, and at a much higher volume.

Testing and quality control

To ensure PCB assembly process is fault-free, we use innovative AOI and X-Ray testing and checking. AOI, or automated optical inspection, test PCBs for catastrophic failure and quality defects by autonomously scanning them with a camera. We use automated testing at multiple stages of our PCB assembly process to ensure all our PCBs are of the highest quality.

Our technology

At Hitech, we utilise the latest advancements in technology for our printed circuit board assembly. Just some of the tech and machines we use includes:

• Wave soldering machine

• Pick and place

• AOI & X-Ray

• Automated conformal coating

• SPI machine

FAQs for HiTech Circuits – PCB Assembly Services

1. What services does HiTech Circuits offer related to PCB assembly?

HiTech Circuits specializes in providing comprehensive Printed Circuit Board (PCB) assembly services. This includes surface mount technology (SMT) assembly, through-hole technology (THT) assembly, mixed-technology assembly, prototype assembly, low-to-high volume production, and turnkey solutions. Our services are designed to cater to a wide range of industries, including but not limited to telecommunications, medical devices, automotive, and consumer electronics.

2. Can HiTech Circuits handle the assembly of complex PCBs?

Absolutely! We are equipped with advanced manufacturing technologies and have a skilled team capable of handling complex PCB assemblies. Whether your project involves high-density interconnects (HDI), fine pitch components, or requires specialized soldering techniques, we have the expertise and resources to meet your needs.

3. Does HiTech Circuits offer turnkey PCB assembly services?

Yes, we offer full turnkey PCB assembly services. This means we can manage every step of your project from sourcing components, PCB fabrication, assembly, testing, and final shipment. Our turnkey solution is designed to save you time and reduce the hassle of coordinating with multiple suppliers.

4. What quality certifications does HiTech Circuits hold?

HiTech Circuits is committed to delivering high-quality products. We are certified under ISO 9001 for our quality management system, ensuring that our processes and products meet international standards for quality and reliability.

5. How does HiTech Circuits ensure the quality of PCB assemblies?

We employ a rigorous quality assurance process that includes automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), and functional testing to detect and correct any defects or issues. Our quality control measures are in place at every stage of the assembly process to ensure that every PCB assembly meets our high standards and your specific requirements.

6. Can I get a prototype PCB assembly before a full production run?

Yes, prototype PCB assembly is one of our core services. Prototyping allows you to test and refine your designs before moving to mass production. We offer quick turnaround times for prototypes to help accelerate your development cycle.

7. What information do I need to provide for a PCB assembly quote?

For a detailed and accurate quote, please provide us with your PCB design files (Gerber files, BOM (Bill of Materials), assembly drawings, and any specific instructions or requirements you have. Additionally, details about the quantity and timeline for your project will help us provide you with a more precise estimate.

8. How long does it take to receive a quote from HiTech Circuits?

We aim to provide quotes as quickly as possible. Typically, you can expect to receive a detailed quote within 24 to 48 hours after submitting all the necessary documentation and information about your project.

9. Does HiTech Circuits support urgent PCB assembly orders?

Yes, we understand the importance of meeting tight deadlines and can accommodate urgent PCB assembly orders. Please contact us with your specific requirements, and we will do our best to meet your timeline without compromising on quality.

10. How can I track the progress of my PCB assembly order?

We believe in keeping our clients informed every step of the way. Once your order is placed, you will be assigned a project manager who will be your point of contact. You can expect regular updates on the status of your order and are always welcome to contact your project manager for any questions or updates.