Hitechpcb provides PCB assembly services in both leaded and RoHS processes, including:

● Plated Thru-Hole Assembly

● SMT assembly including BGA Assembly, smallest

placement: 0201

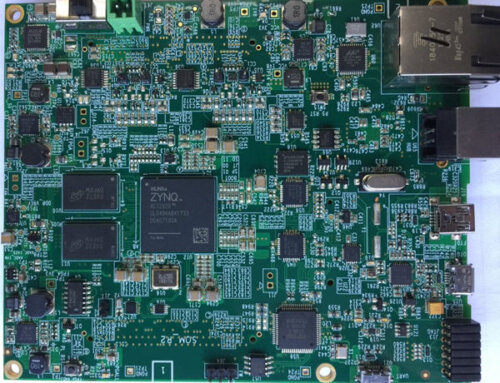

Using traditional methods, Hitechpcb staff carry out manual assembly of conventional technology PCBs in prototype, small volumes. Hitechpcb can supply medium and large volumes printed circuit board assembly, and can work many surface mount packages including BGA, Chip Scale Packages and passives down to 0201, a high level of placement accuracy, solder joint integrity and quality is consistently achieved.

1. Through hole board assembly

Our Thru-hole assembly process allows for your parts to be hand prepped, loaded and inspected on an assembly line after which they are either wave-soldered or hand soldered. All assembled boards then go through final inspection, ensuring the highest quality before delivery to you.

2. SMT assembly

We use Juki and Panasonic assembly line for SMT assembly. Our SMT assembly capability is:

• • Component height: 0.2-25mm

• • Min. Package: 0201

• • Min distance among BGA : 0.25-2.0mm

• • Min. BGA size: 0.1-0.63mm

• • Min. QFP Space: 0.35mm

• • Min. assembly size: (X*Y): 50*30mm

• • Max. assembly size: (X*Y): 350*550mm

• • Pick-Placement precision: ±0.01mm

• • Pick-Placement range: QFP,SOP,PLCC,BGA

• • Placement capability: 0805,0603,0402,0201

• • Via in Pad, Blind & Buried Vias capable

• • Rigid pcb, Flex pcb, Rigid flex pcb capable

• • High pin count press fit capable

• • SMT capacity per day: 1200,000 point