Ceramic PCB Manufacturer

With recent advances in the market, Ceramic PCBs have become a more viable option for PCB designers. With the continuing requirements for miniaturisation, microelectronics and high-power LED packages, the need for substrates capable of withstanding high operating temperatures, whilst offering outstanding thermal performance is a must.

Ceramics have been widely used in electronics/electronic components for years due to their thermal, and mechanical advantages. With recent advances in technology and manufacturing capabilities, they are now replacing entire Ceramic PCBs.

Since their introduction, Ceramic PCBs have received enormous attention from the industry as an effective solution to a range of electronic issues. The superior Thermal Conductivity of ceramics being the leading reason that more and more industries are turning to ceramics for Ceramic PCB design.

In addition to this, Ceramic material can withstand high operating temperatures (up to 350°C) and has a very low CTE (Coefficient of Thermal Expansion), allowing for additional compatibility options for circuit design.

See a full list of advantages below:

- Superior values of Thermal Conductivity (up to 170W/mK)

- Higher operating temperatures up to 350°C

- Lower CTE

- Suitable for high frequency applications due to low signal loss

- Possibility for Hermetic packages with 0% water absorption

DK THERMAL CAPABILITIES

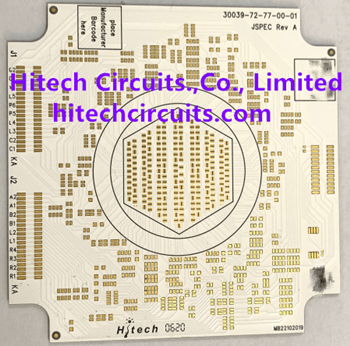

DK Thermal specialises in Alumina Oxide (Al2O3) PCB and Aluminium Nitride (AIN) PCB boards. Direct bond copper (DBC) and direct plated copper (DPC) technologies are used for the circuitry depending on the requirements and/or applications.

Ceramic PCB technology:

DPC Ceramic PCB

DBC Ceramic PCB

HTCC Ceramic PCB

LTCC Ceramic PCB

HTFC Ceramic PCB