Types of PCB Failure analysis test

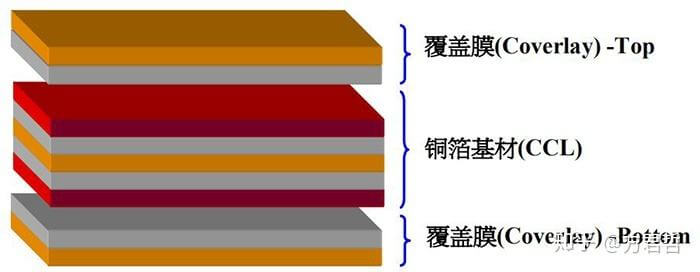

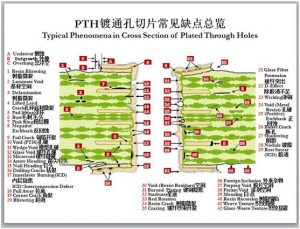

1.Micro-Sectioning Analysis

Micro-sectioning also know has cross-sectioning or metallographic preparations are used for PCB testing.

Thermo-mechanical failures

Component Defects

Opens or shorts

Processing failure due to solder reflow

Raw material evaluations

2.Solderability Testing

Solderability test work for a variety of applications and quality standards

PCB Coating Evaluation

Solder Evaluation

Flux Evaluation

Benchmarking

Quality control

The PCB failure analyst should have the experience to differentiate the various conditions and understand the requirements of the testing technique

3.PCB Contamination Testing

Contaminations can be the reason for part failure including degradation metallization Processing of printed circuit boards is taken place in an extremely clean environment designed to keep the component from contamination to be processed and assembly without part failure.

Copper etching liquid

Hot air leveling fluxes

Electrolytic solutions

Water-soluble soldering

4.Optical Microscopy/SEM

Optical Microscopy may be one of the most popular testing methods many customers choose optical microscopy because of its speed and accuracy to detect faults and problems associated with soldering and assembly. The process of optical Microscopy uses a high power microscope with visible light this microscope can reach up to 1000X, has small depth field and shows features in a single plane.