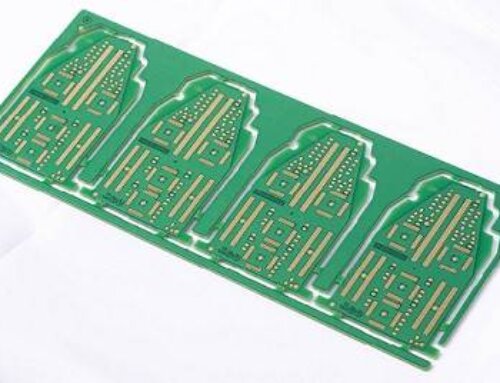

Copper Plating (Electroless Plating Copper) commonly known as copper. Hole PCB printed circuit board technology is one of the key manufacturing technology. Strictly control the quality of Hole is to ensure the final quality of products, and control the quality of the copper layer is the key. Daily use of the test control method is as follows:

1. Determination of rate of electroless copper:

(1) Materials: epoxy substrate after etching of copper, size 100 × 100 (mm).

(2) Measurement procedures:

A. The sample in the 120-140 ℃ bake 1 hour, then use the analytical balance weight W1 (g);

B. In the 350-370 g / l of chromic anhydride and 208-228 ml / l sulfuric acid mixture (temperature 65 ℃) in the corrosion of 10 minutes, wash with water;

C. In addition to the treatment of chromium waste water (temperature 30-40 ℃) 3-5 minutes, washed;

D. Prepare according to the provisions of process conditions, activation, but also liquid in the treatment;

E. In the copper solution (temperature 25 ℃) copper half-hour, clean;

F. Specimen bake 1 hour at 120-140 ℃ to constant weight, W2 (g).

(3) Copper rate calculation:

Rate = (W2-W1) 104/8.93 × 10 × 10 × 0.5 × 2 (μm)

(4) To compare and judge:

The result of the determination of the data provided with the process data to compare and judge.

2. Determination of the etching rate etching

Heavy copper PCB, Heavy copper board, Power PCB

(1) Material: 0.3mm copper clad board, oil, brush plate, and cut into 100 × 100 (mm);

(2) Measurement procedures:

A. Sample in hydrogen peroxide (80-100 g / l) and sulfuric acid (160-210 g / l), 30 ℃ for 2 minutes corrosion, cleaning and deionized water wash;

B. Bake 1 hour at 120-140 ℃, constant weight and weighed W2 (g), the sample is also here in the corrosion conditions of constant weight before weighing W1 (g).

(3) The calculation of the etching rate

Rate = (W1-W2) 104 / 2 × 8.933T (μm / min)

Where: s-sample area (cm2) T-etching time (min)

(4) To determine: 1-2μm / min corrosion rate is appropriate. (1.5-5 min etching copper 270-540mg).

3. Glass cloth test methods

The process in the Hole, activation, electroless copper is the key process. Despite the qualitative and quantitative analysis of ionic liquid palladium and also to reflect the reduction properties of activated, but not as glass cloth test reliability. Conditions in the glass cloth copper the most demanding, most indicative of activation, reduction and the performance of liquid copper. Are described as follows:

(1) Material: 10% of the glass cloth in a solution of sodium hydroxide was from pulp processing. And cut into 50 × 50 (mm), around the end of the removal of a number of glass to make glass to disperse.

(2) Test procedure:

A. Copper process the sample according to procedures for processing;

B. copper into solution, and 10 seconds later the glass cloth copper terminations should be completely black or dark brown, 2 minutes on all sink, 3 minutes after the copper better; on SHEN copper, 10 seconds glass cloth ends after the copper to be fully 30-40 seconds, the entire sink with copper.

C. Judgment: If the copper to achieve the above results, indicating activation, reduction and copper properties, and anti the poor.

Hitech is professional PCB manufacturer, which provides 3OZ ~ 12OZ good quality Heavy Copper PCB at competitive price. Visit www.hitechcircuits.com to know more about our PCB products.