PCB Assembly process–Electronic assembly quote and DIP assembly and component source

The PCB assembly is the process of mounting or placing electronic components which give the board its functionality. The electronic components can be mounted by manual and automatic techniques, and then they are soldered in place.

It would help if you did not confuse it with printed circuit board (PCB) manufacturing which involves the production of the PCB and creating prototypes. Covers the installation of electronic components during the assembly process, and the board is called the PCBA or printed circuit board assembly.

1.Printed Circuit Boards Assembly Process

Differences in Printed Circuit Boards Assembly Process

You can use a different type of technologies to assemble the electronic components on a PCB. The main methods include Thru-Hole Technology (THT), Surface Mount Technology (SMT) and Mixed technology.

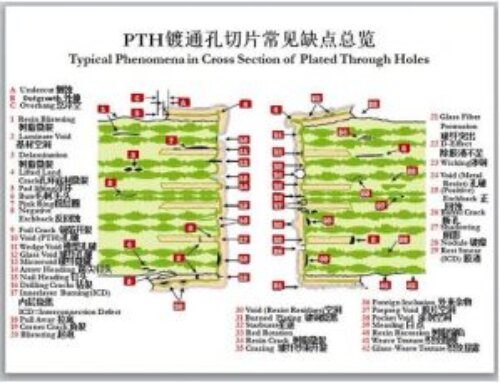

1).Through-Hole Technology (THT)

THT assembly makes use of both manual and automatic processes to place the components on the PCB. Proceed as follows

Placing Components

Electrical engineers manually place the components on the PCB according to specifications. It has to be done quickly and accurately with full compliance to operation standards or regulations of THT assembly process for proper functioning.

Examining and Correction

You need to check if all the electronic components on the PCB have been placing accurately. It can be done automatically with the use of a transport frame. If you find any errors or mistake, the engineers can quickly rectify it.

Wave Soldering

These electronic components have to be soldered to the board in this step. You can do it manually, but a far more efficient and automated process called Wave soldering can be used.

2) Surface Mount Technology (SMT)

SMT?is the automatic process of placing or mounting electronic components on a PCB. SMT enables you to speed up the production process, but there are increased chances of defects. For this reason, the process also employs failure detection for creating functional products.?

Applying Solder

You have to use a solder paste printer to apply solder to the PCB. A solder screen or stencil is used to ensure the proper application of solder at valid points where electronic components will be placed.

Placing Components

A pick-and-place machine is used to mount the electronic components after solder printing. The machine automatically mounts the IC or components through component reels. They components reels are responsible for feeding the components to the machine which are then fixed onto the PCB.

Reflow Soldering

This step uses a specialized oven to harden the solder paste so that the components can be fixed firmly to the board. The PCB is carried inside a series of heaters which raise the temperature of the board to 250 degree Celsius. The high temperature melts the solder on the board

Next, the PCB moves through a series of cooler heaters which bring down the temperature and help the solder to harden. That adheres all the electronic components firmly to the PCB.

Mixed Technology

In the modern age, electronic products have increased in complexity requiring the use of different electronic components on PCBs. You will find the use of both THT and SMT technologies in a single PCB which contains both surface mounted and through-hole components.