DESIGNING FLEXIBLE PRINTED CIRCUIT BOARDS (Part Two)

High-density-Interconnect (HDI) Flexible PCBs

When there are no adequate options provided by typical flexible circuits, HDI PCBs come into play by incorporating fine features like micro-vias, better layout, construction, and design. In addition to the above features, other features include; highly dense flex circuitry, Increased functionality, and smaller form factor.

HDI technology offers improved electrical performance, access to advanced IC package use, and better reliability though it makes use of thinner materials.

Benefits of Flex Circuits

As for a ribbon cable or discrete wiring replacement, customized repeatable routing supplied by flex circuits trails all through the assembly. Because of their greater reliability, they can reduce service calls.

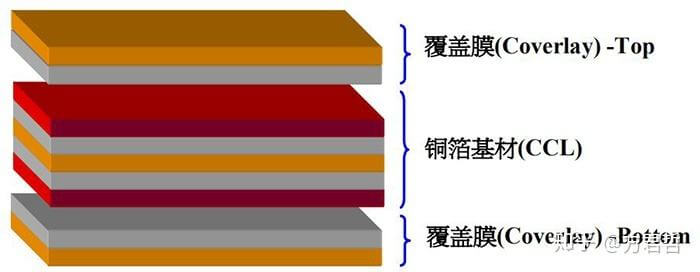

Polyimide is a dielectric layer that covers and offers protection to the circuit more than the simple sold mask. This layer is used by flex boards to cover the conductors of flex circuits. Other based and cover materials are used by manufacturers so as to handle a wider range of harsh surroundings and ambient conditions.

Flex boards are capable of weathering flexing long duty cycles though they can be very thin. To resist and being able to carry millions of flexing cycles, these boards can be strengthened by using appropriate design materials. This is to ensure that there are no interruptions while carrying power and signal.

When facing high acceleration and/or vibration, the high ductility and low mass of flex circuits is of great advantage. When under the same working conditions, the impact and stress on a rigid PCB and its solder joints and components are far more than that faced by the solder joints on a flex PCB

The advantages of flex circuit boards make them perfectly suitable for numerous applications in areas like Medical, Consumer Electronic, Military, Aerospace, Industrial, Automotive, Transportation, and communication.

Cost Impact

In general, though rigid PCBs are less expensive than flexible circuits, cost increases with the count of the layer. Hence, to minimize cost, some considerations must be done. For example, using one four-layer circuit may be more expensive as compared to a two double-layer circuit.

In favor of flex circuits, some other factors might reduce the overall cost. For example, layers and space could be saved by folding a flexible circuit. Depending on the condition, the investment of time in the assessment of a project has potentially led to substantial general savings.

Hitech PCB offers detailed and completed printed-circuit-board development resources.