Controlled Impedance Designs from PCB manufacturer—Hitechpcb

Cost

China PCB Manufacturer––HITECHPCB is one of the largest PCB fabricators in China, and is regularly studying new materials and methods to help save costs.

Many suppliers of this technology have developed this specific niche. As a result, their customers must absorb the supplier’s entire overhead via the piece price.

China PCB Manufacturer —HITECHPCB remains a production PCB supplier with a strong focus on prototyping through the production of advanced technologies.

However, our facility is also constantly processing higher volumes of standard technology PCBs.

As a result, our overhead is spread over a larger number of production panels and projects, allowing us to charge a fair and reasonable price to our customers that are often not indicative of the high level of technology in the products we produce.

Design Verification

Designers often do not have access to the latest tools (or any tools in some cases) to calculate proper impedance values for their designs.

Also, even when they do, different aspects of the PCB fabrication process that affect impedance are often not incorporated into their models for impedance line calculations.

To avoid moving on to production with a flawed design, HITECHPCB has purchased the latest impedance calculation software from Polar. We use this software to verify each impedance calculation against our actual stack up for the board. Our stack models incorporate real-life prepreg compression values based on glass type, resin percentage, and copper retention rates.

Etching

Inaccurate etching can have a large impact on the impedance characteristics of traces. Inaccuracies in etching include over-etching, undermatching, and non-linear etch rates, which are often due to “puddling”.

Puddling is a result of fluid dynamics. Since etching is a horizontal process, etching chemistry is sprayed onto the top and bottom of the panel. While the chemistry that is sprayed from the bottom falls back off the panel, the chemistry sprayed from the top remains on the panel, forming a puddle.

This puddle then absorbs much of the force of the newly sprayed chemistry. Since etching is as much a function of the physical force of the chemistry hitting the copper as it is a chemical reaction, the etch rate on the top side of the panel is reduced.

This requires the operator to slow down the line speed in order to properly etch the top surface. As a result, the bottom side is often over-etched.

PCB Mnaufacturing—HITECHPCB has recently installed Hollmuller etching lines for both inner and outer layers. These lines have the latest anti-puddling spray technology incorporated within them.

This technology uses a specific spray pattern and nozzle arrangement, along with an oscillating spray bar, to “sweep” away old etchant so that newly sprayed etchant is sprayed directly on to the copper surface.

Furthermore, these lines automatically control temperature and chemistry concentrations to insure uniformity throughout the production process.

Product Final Verification / Testing

Even though we have applied the best techniques for design verification and etching, other factors may still negatively affect the characteristic impedance of actual traces on production.

To prevent substandard product from moving on to the customer, we have purchased a Polar CITS500s Controlled Impedance Test System.

This system tests coupons that our CAD operators insert in multiple places on every panel that is reflective of the characteristic impedance designs used in the boards.

Any coupons that fail test cause surrounding PCB’s to be rejected in-process so that they are not shipped to the customer.

Our Categories:

• Multilayer PCB ︱Multi-layer pcb

• HDI PCB ︱High density PCB︱High Density Interconnect PCB

• Metal Base PCB ︱Aluminium PCB︱Aluminum pcb

• Flexible PCB︱rigid-flex PCB︱Flex-rigid PCB

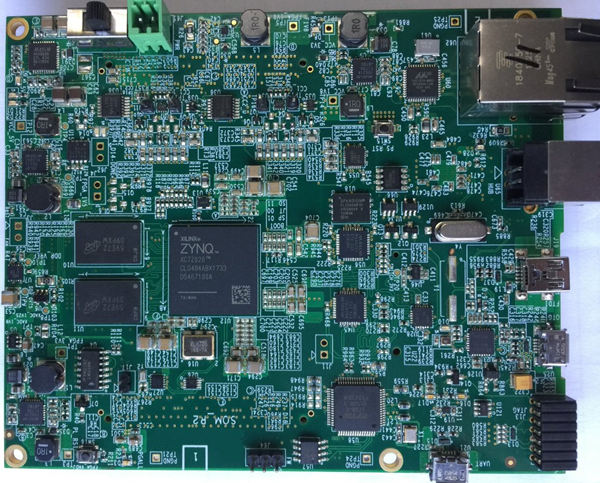

• Impedance Control PCB

• Quick turn pcb︱Express PCB prototype

• High Frequency PCB

• Heavy Copper Power PCB

• China PCBA ︱PCB Assembly

• China PCB manufacturer