Professional China PCB Manufacturer Tells You Some Knowledge about Printed Circuit Board

Printed Circuit Boards (PCB) are essential in the world of electronics. PCBs help to connect electronic components and enable them to work together seamlessly. They come in different shapes and sizes with various designs and layouts suitable for different applications. A Professional China PCB Manufacturer, as a producer of PCBs that meet both international and national standards, knows how important it is for you to have knowledge about printed circuit boards.

In this blog post, we will share some essential knowledge that every electronics enthusiast needs to know about Printed Circuit Boards, including their history, types, manufacturing process, materials, and applications.

1. History of Printed Circuit Boards

The invention of Printed Circuit Boards dates back to the early 20th century. It was during that time that scientists and engineers discovered that electronic components could be connected to create circuitry using a flat surface. In the late 1940s, PCBs were made commercially available, and they have since become the standard for most electronic devices.

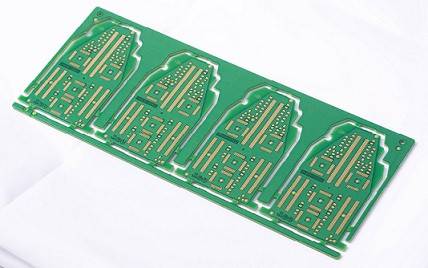

2. Types of Printed Circuit Boards

There are different types of Printed Circuit Boards, each suited to specific electronic needs. The single-sided PCB is the simplest and most basic type of PCB, where all components are on one side of the board. Double-sided PCBs use both sides of the board, providing more space which, in turn, allows more components to be connected. Multilayer PCBs are similar to double-sided PCBs but consist of more than two layers. Their complex designs make them expensive to manufacture, but they are suited to high-density miniaturization.

3. Manufacturing Process

The PCB manufacturing process involves several steps, including designing the layout and the printed circuit board, copper patterning, etching, drilling, coating, and finally, electrical testing. The manufacturing process may differ depending on the type of board required. A Professional China PCB Manufacturer uses different techniques to manufacture PCBs such as SMT, through-hole, and mixed technology.

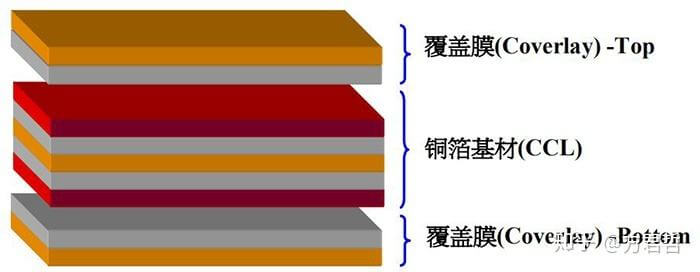

4. Materials

There are different materials used in manufacturing PCBs. Some of the most commonly used materials include FR4, a fiberglass-reinforced material that offers high dimensional stability, high-temperature resistance, and low moisture absorption. Polytetrafluoroethylene (PTFE), a polymer that has excellent dielectric properties, makes it suitable for high-frequency applications, and Rogers R4000, a thermoset stable laminate material that’s designed for higher frequency applications of more than 10 GHz.

5. Applications

Printed Circuit Boards are essential in today’s electronics industry, and they have countless applications. PCBs are found in everyday devices such as remote controls, calculators, MP3 players, and even cars. Some industries heavily dependent on PCBs include the medical device industry, aerospace industry, and military industry, where most of the complex electronics require high-quality PCBs.

Conclusion:

In conclusion, a Professional China PCB Manufacturer provides Printed Circuit Boards that have become the building blocks of most electronics devices, providing a way for electronic components to work together in a seamless, integrated circuit. Understanding the types, manufacturing processes, materials, and applications of PCBs is crucial in the electronics industry. We hope this guide has helped you understand more about PCBs and how they are made and used in various applications. As technology advances, we can expect to see more complex and sophisticated PCBs designed to meet the ever-increasing demands of modern electronics.