Aluminum based PCB︱MCPCB

-

What is MCPCB?

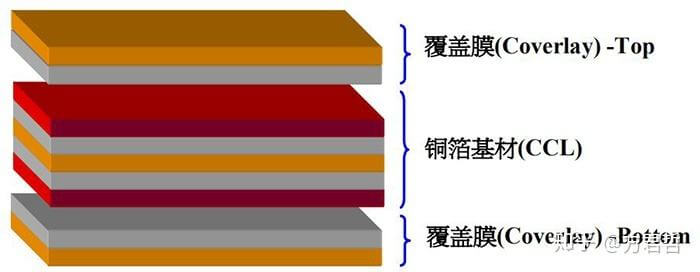

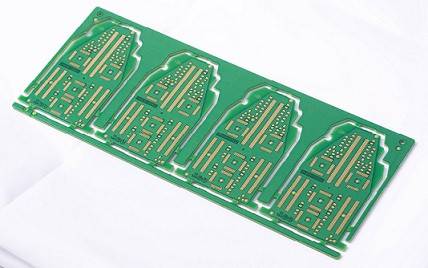

MCPCB stands for Metal Core Printed Circuit Board. It is designed with a metal core layer as a heat sink to dissipate heat generated by the electronic components. Aluminum is the most commonly used metal for MCPCBs due to its high thermal conductivity and low cost.

-

Advantages of MCPCB

- Excellent heat dissipation: MCPCBs are designed to dissipate heat generated by the electronic components, making them ideal for high power and high heat applications.

- Easy to route and assemble: MCPCBs are designed with a metal core layer that provides excellent stability, making them easy to route and assemble.

- Cost-effective: Aluminum is a low-cost metal, making MCPCBs an affordable choice for many industries.

-

Applications of MCPCB

- LED lighting: MCPCBs are widely used in the LED lighting industry due to their excellent heat dissipation capabilities.

- Power electronics: MCPCBs are also used in power electronics such as motor control, power supplies, and inverters.

- Automotive industry: MCPCBs are used in automotive applications such as electric cars, fuel injection systems, and aerospace.

-

Designing MCPCB

- Trace width and spacing: The trace width and spacing for MCPCB should be designed in accordance with the current carrying capacity and electrical insulation requirements.

- Thermal conductivity: It is important to select a metal with high thermal conductivity, such as aluminum, for the metal core layer.

- Soldermask: MCPCBs should have a soldermask to prevent solder bridging between adjacent pads.

- Assembly: Assembly of MCPCBs should be carried out using techniques such as wave soldering or reflow soldering.

-

Ordering MCPCB

- When ordering MCPCBs, it is important to provide the PCB manufacturer with detailed specifications such as board thickness, metal core layer thickness, trace width and spacing, and surface finish. Hitech Circuits Co., Limited is a good choice for you for MCPCB manufacturing, order from the original PCB factory without any middle cost.

- The PCB manufacturer can also assist with the design and layout of MCPCBs, providing advice on material selection and board size.

In conclusion, MCPCBs are a popular choice for high-heat and high-power applications due to their excellent heat dissipation capabilities. When designing or ordering MCPCBs, it is important to consider factors such as trace width and spacing, thermal conductivity, solder mask, and assembly techniques.

Hitech Circuits Co., Limited

Source from : www.hitechcircuits.com

E-mail: [email protected]