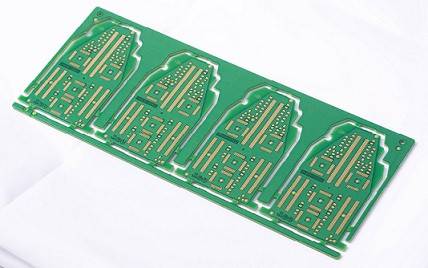

Why Rapid PCB Prototyping is so Important?

As the need for manufacturers to increase their time-to-market speed increases, the need for faster PCB prototyping also increases. Rapid Printed Circuit Board Prototyping is usually the step that takes the longest in the whole process and, as such, needs to be shortened in practical ways because new software and features can only be tested out on prototypes. Let’s take a more in-depth look at why rapid PCB prototyping is so important.

Short Turnarounds

The best express PCB prototyping methods all have one thing in common: short turnaround times. This means that new printed wiring board prototypes can be created merely within hours, whether it be the initial design or one of many future revisions. It’s virtually invaluable to consider the lead time for any PWB prototyping method, whether or not you are creating PWB prototypes yourself in-house, or using an outside service company to supply PCB prototypes to you.

Increased Ability to Edit Designs

When you can build and buy printed wiring board prototypes as you need them, you gain the ability to evaluate your board designs and see how effective they will be. It’s impossible to gain this kind of insight without the production of prototypes, and the more you have produced, the more you will learn. Making quick turn pcb prototypes also can give you the very important ability to find out what flaws are in your design before they move too far along in PCB manufacturing the process. Quick turn pcb Prototypes allow you to identify potential errors and fix them before your production build goes live. This also allows you to reduce your time-to-market speed.

More Creativity

With a high number of prototypes being made available, your PCB designers will have much more freedom to explore ideas. Working on prototypes allows them to exponentially increase their knowledge of your design and try new techniques that allow for better functionality, while at the same time meeting your deadlines and keeping the momentum of a project rolling.

Cooperation Between Departments

Another huge benefit to very rapid PCB assembly prototyping services is the fact that it also allows you to create and introduce new hardware variations into the very same line of a product. Both private and business buyers are in the market for hardware that is specifically tailored to fit their individual needs. This means the introduction of products with new colors, sizes, features, and price points as well.

In Conclusion

The ability to have your PCB prototypes quickly produced greatly reduces your cost of development and the time required to create a new product. This, in turn, gives you the ability to drastically shorten your time-to-market, which then gives you a valuable leg up on the competition.