Project Description

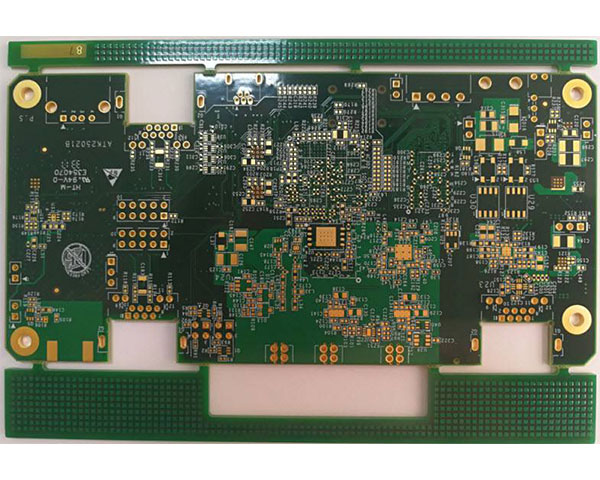

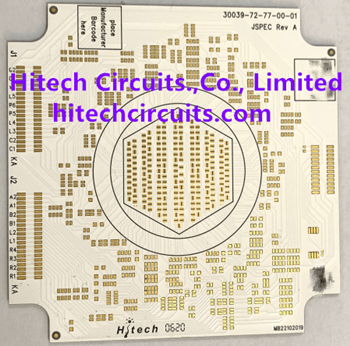

Teflon PCB

Hitech Circuits provide various well-known brand Teflon PCB Laminate, for example: Rogers PCB, Teflon PCB, taconic Teflon PCB. Rogers and the Taconic Teflon PCB Lamination.

High Frequency Teflon PCBs are an essential item for any modern communications device. With amazing high thermal resistance and impressive durability. Email [email protected] if you are looking Teflon pcb supplier in China.

What is Teflon PCB?

Teflon is a brand name for Polytetrafluoroethylene. PTFE is known for its nonstick and non-reactive surface. Teflon is a well-known material used in the PCB manufacturing of several products. Teflon PCB is an electric circuit that is equipped with better capacities and enhanced connections.

Teflon PCB is a synthetic resin material utilized in non-sticky applications. This material is manufactured by polymerizing tetrafluoroethylene. Teflon PCB material can resist high temperatures. Due to this, it is commonly used for high-frequency PCB.

It features properties like low dissipation factor, cold resistance, low coefficient of thermal expansion, chemical resistance, and high heat. Teflon PCB manufacturers design this PCB to offer outstanding advantages to users.

Polytetrafluoroethylene is a material known for its resistance to moisture, grease, chemicals, and oil. PTFE PCB features high lubrication, no adhesion, weather resistance, and high insulation. This material is used in the production of PCB ideal for electronic appliances.

Properties of Teflon PCB

A Teflon PCB board has great mechanical, thermal, and electrical properties. This board is used in applications demanding high frequency and high temperature. Below are some of the properties of this printed circuit board;

Great chemical resistance: This material has the ability to withstand chemicals. When exposed to chemicals, oils, and grease, its original properties don’t alter. PTFE boards can be used in a chemical reagent environment.

Low temperature resistance: Teflon PCB material features great mechanical toughness. Even in cases where the temperature reduces to -196 degrees Celsius, it can still maintain 5 percent elongation.

Weather resistance: This is one of the best properties of this material. Teflon PCB can withstand any weather condition. This makes them durable and reliable.

Low dissipation factor: Teflon PCB board offers a low dissipation factor which makes it a good insulator system. This material is ideal for high-performance and high-quality electronic systems. It is ideal in applications like radar systems and radio frequency.

Non-stick: This material is non-adhesive and non-stick. PTFE is a combination of carbon atoms with fluorine atoms attached to every carbon atom. These strong bonds make this material to be unreactive.

Low water absorption: PTFE PCBs can be used in humid environments since they feature low water absorption. This means that this board can withstand moisture.

Exceptional electrical properties: PCB Teflon features low dielectric loss and dielectric constant over a high frequency. This material offers volume resistivity and high breakdown voltage. Its dielectric constant is measured at 2.0.

Advantages of Teflon PCB

PTFE is a useful material for the fabrication of PCB. Teflon PCBs have their unique advantages.

Temperature resistance: Teflon printed circuit board can survive extreme cold and heat. This is a major reason it is used in military and aerospace applications. This board can work from -454 to 600°F and -270 to 315°F. Its ability to withstand any temperature prevents it from cracking.

Great dielectric strength: Due to the high dielectric strength of this board, it is non-conductive. It works perfectly as an insulator. The insulating capability of this material protects equipment from electrical breakdowns.

Durability: PTFE PCB is an ideal option to consider since it is very durable. It can withstand oxidation, ultraviolet rays, embrittlement, or discoloration. It is a cost-effective option because of its long-lasting nature.

Mechanically rigid: Teflon PCB is mechanically stable. This makes it ideal for use in applications that are exposed to high levels of mechanical stability. The thermal conductivity of Teflon PCB is great.